3 Benefits Of Outsourcing Online Store Logistics To 3PL

Introduction

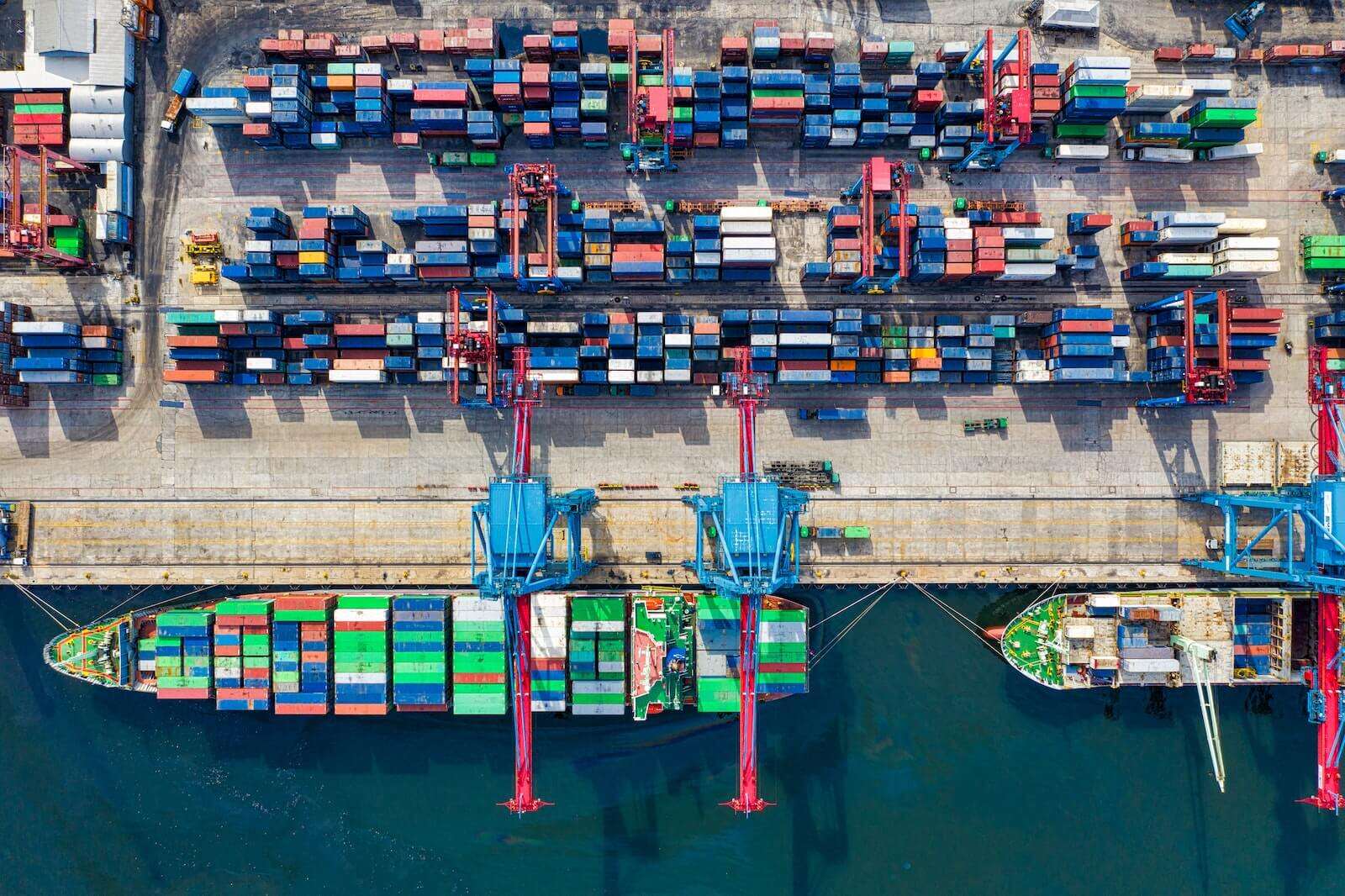

The world of e-commerce is a rapidly changing one, and managing its logistics can only take years of development and resources--it's not simple. As online shops expand in scale, efficient warehousing order fulfillment and shipping are becoming increasingly critical. This is where Third-Party Logistics (3PL) comes in, offering tailored solutions to meet these challenges. Outsourcing logistics to 3PL providers yields several benefits. It is cost saving and accessible expertise with resources. Moreover, that way the customer experience will be better. This paper goes into these benefits and points out why and how online shops can exploit 3PL services for their gain.

Benefit 1: Cost Savings

One of the primary reasons online shops think to outsource their logistics is the potential for cost reduction. 3PL providers can offer significant advantages in this regard:

- Reduced administrative costs: By outsourcing this work online retailers are able to avoid the high costs of keeping up their own warehouses and transport fleets. In many cases 3PL providers by that scale can do so for a lower cost, which means more direct profit for the online store.

- Focus blossomed into the core business: When a 3PL handles their logistics, online stores are relieved from the tasks and diverted to their creative energies for handling main-business - such as producing products, advertising customers (through marketing), customer acquisition. This strategic concentration can lead to increased competitiveness and growth.

- Case Studies or Illustrations: There are plenty of examples from e-commerce companies demonstrating the cost advantages of 3PL partnerships. For instance, one specialty food online retailer claims that by teaming up with a third-party logistics provider who provided consolidated shipments and optimized inventory management they were able to reduce their logistics expenses by 25%.

Benefit 2: Talent and Skills

- Specialized talent and sophisticated resources can be accessed from using a 3PL supplier, 3PL providers typically invest in the most advanced warehousing management systems and order fulfillment technologies. This allows online stores to choose solutions which are at the forefront of current technology, rather than limiting themselves to those they can afford or operate by leadline alone.

- With the depth of practical experience in logistics and best practices that 3PL providers possess, they can provide optimized plans to match different industries’ particular requirements. This expertise is invaluable for any online store as it helps them negotiate through complicated logistical problems so as to improve overall efficiency and streamline operations.

- Scalability and Flexibility: Online businesses experience wide fluctuations in demand. When the peak season arrives, a 3PL supplier can expand its service capacity at will in response to such requirements by giving online retailers the agility they need during periods of high sales and without having to bear overheads for excess capacity.

Benefit 3: Customer Experience Enhanced

- The customer experience is a key differentiation point for online retailers. For online stores, outsourcing logistics can greatly improve this key side of the business:

- Faster Order Fulfillment: Many 3PL providers have extensive distribution networks, enabling them to ship orders from the nearest warehouse as soon as possible This can cut down on delivery time and make the entire order process faster.

- Better Service Quality: By making use of 3PL suppliers’ expertise, online stores can ensure that their products are bundled and handled carefully before they go out; this can help alleviate future problems caused in transit during transportation elsewhere. Such fine detail almost always results in increased satisfaction on the part of customers.

- Customer Support and After-Sales Service: Many 3PL suppliers provide full customer support services. They can handle questions about shipping, tracking, returning goods, etc. This allows the online store staff to concentrate on other activities in their company while simultaneously ensuring that customer service levels are maintained.

Further Problems and Factors Need to be Considered

Althought many online businesses find it beneficial to outsource its logistics to a third party, there are also the following problems and factors need to be taken into account:

- Choose Your 3PL partners wisely: You've got to make sure that the 3PL provider you pick fits in with the overall objectives of your online store. Such factors to consider include evaluating the carrier's technology, transport network reliability and reputation for customer service.

- Guarantee the Transition: The switch to a 3PL provider must be carefully planned and managed, in order to be sure things will run smoothly. This could mean meticulous inventory checks, system integration and training for employees.

- Continue to Monitor Performance and Communicate : A successful partnership with your 3PL provider calls for continuous dialogue and an ongoing effort to track performance. If you establish clear KPIs and periodically review service standards, both sides can keep working together productively and benefit from the relationship.

Summary

All in all, outs

ourcing logistics to a 3PL provider offers substantial benefits for online stores, including cost efficiencies, superior knowledge and resources; and a better customer experience. The key to gaining these advantages, however, is selecting right 3PL partner, managing the transition successfully, and maintaining a strong communication-based partnership. By doing this, the power of 3PL services can be used to keep their rhythms well lubricated and online stores can offer better service to satisfy customers.